We’ve all been told that if we want to succeed in life and in business, that taking pride in what we do is of critical importance. There is a certain thrill that comes from doing something right not just doing something “good enough”.

Machining with Pride

Aug 20, 2018 2:38:54 PM / by Travis Miller posted in Contract Machining, job shops, Machine Shop

Adversity, Leadership, and… Pizza?

Aug 3, 2018 4:09:31 PM / by Travis Miller posted in Insider, job shops

I’ve learned a lot in a short time about being a leader. The list of positives and successes far outweigh the challenges and failures, yet much like everything in life there are ebbs and flows, good times and bad, peaks and valleys. Being a leader offers up rewarding experiences like:

Ways to Categorize Mandatory Spare Parts

Aug 3, 2018 4:07:14 PM / by Mike Toth posted in Insider, Machine Tool, Maintenance

Owning a Bardons & Oliver Machine is a great investment for your company. Maintaining your system will result in many years of productive service for your company. Included with the instruction manual for your machine is a suggested spare parts list. These are necessary parts that will play an important role in keeping your machine running longer and getting it running sooner whenever it has to be taken out of service for preventive maintenance and repair.

History, tradition & expertise: what is important to you when choosing a Machine Tool Partner?

Feb 16, 2018 4:26:49 PM / by Jon Beattie posted in Machine Tool

Deciding to purchase a new machine can be a complex task. There are many decision makers and influencers involved to help evaluate current production needs and future business growth. The most successful companies know the importance of having the best possible machine tool partner in order to make their project flourish.

Precision Turning and Your Large Diameter Project

Dec 15, 2017 3:39:47 PM / by Travis Miller posted in Contract Machining, job shops, Machine Shop

The average human hair measures between .003” and .006”. Now picture a 50” OD with a +/-.001 tolerance. Impressive, correct? Now consider that a 5 degree temperature difference between the part and the piece of inspection equipment used to measure it would throw off the reading by about .0015.

B&O’s Latest Control Retrofit: Giving Trusted and Reliable Equipment New Life

Dec 8, 2017 3:58:19 PM / by Jon Beattie posted in Machine Tool, Company News

B&O’s Latest Control Retrofit: Giving Trusted and Reliable Equipment New Life

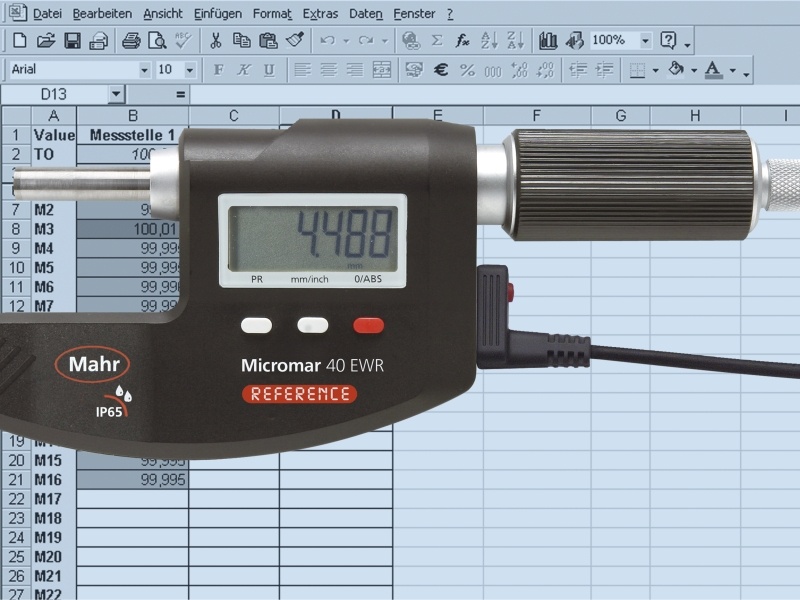

Investing in Quality: Calibrated Gages

Nov 3, 2017 11:04:03 AM / by Travis Miller posted in Contract Machining, gage calibration, iso 9000

Investing in Quality: Calibrated Gages

A master woodworker does not use a beat up yardstick while crafting a beautiful table. A world class clothier doesn’t eye ball your body before crafting an exquisite suit. A 4-star chef will use precise tools to measure ingredients to repeat a spectacular recipe. Why would you trust your precision metal work to a shop who didn’t invest in properly calibrated gages and a staff trained to use them correctly?

Learning to Lead (Lessons from my Fiancé)

Oct 26, 2017 3:04:41 PM / by Travis Miller posted in Insider, Contract Machining

I think it’s important to get two things straight before we hop into the topic of leadership, and leading. First, I do not claim to be a great leader, I don’t even claim to be a really good leader. I’m a better leader than I was when I took a leadership role 20 months ago, and I try to get better every single day. Second, my fiancé is smarter than me… by a lot.

Avoiding the Most Common Mistakes in Machining (Focus, Offsets, and You)

Oct 6, 2017 1:35:49 PM / by Travis Miller posted in Insider, Contract Machining

We’ve all done it. You check a bore, an OD, or any feature, make your adjustment, push start and experience that sinking sensation in your gut as you go to check the result. It’s bad. It’s out of tolerance. If you’re lucky, you just have to adjust and cut it again. If you’re really unlucky, you crash the machine and the rest of your day is spent trying to recover.

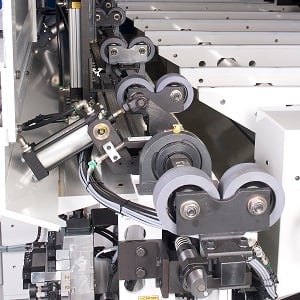

High Performance Cutoff Equipment for Your Steel Service Center Needs

Aug 30, 2017 11:23:19 AM / by Jon Beattie posted in Machine Tool, Company News

In today’s competitive market, offering your customers value-added solutions allows them to reduce costs and increase capacity. Providing more complete parts in less steps creates a streamlined manufacturing process.