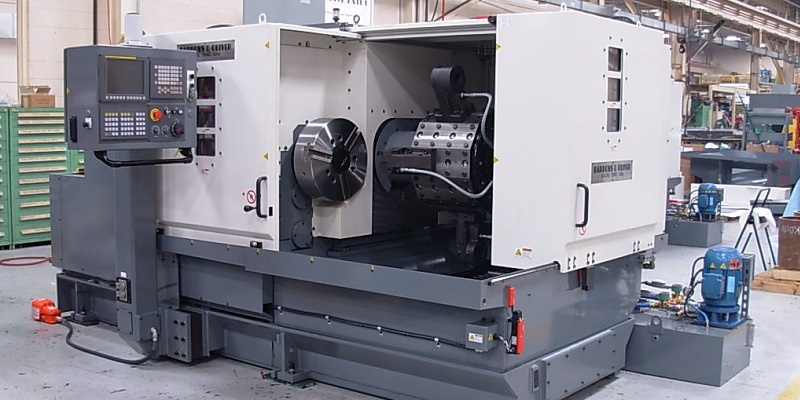

- The chuck sizes on these machines range from 12" to 32", with spindle mounted faceplates from 15" to 44" in diameter

- The unique column design allows for true 12-station interference-free tooling

- The machine design also provides superior operator access to the chuck for ease of part load/unload, as well as workholding changeover

- All critical mechanical and electronic components are located outside the chip and coolant environment for superior machine reliability and proven long service life

The column-style turning machines are built on rigid, heavy cast iron or composite machine bases and slides for maximum stability and durability.

Other features of this line of machines include:

- 2-speed, gear-driven headstock for maximum cutting horsepower at low RPMs

- Highest cutting horsepower available on any 2-axis turning machine in size class

- Large interference-free part swing envelope

- Large-capacity chip conveyor easily handles heavy chip removal rates

- Self-contained machine design allows for easy relocation within customer’s plant

- Taper roller bearing mounted spindle systems provide superior weight-carrying capacity for heavy workholding packages and workpieces

- Optional angular contact ball bearing mounted spindle systems provide maximum thru-hole capacity at the highest possible spindle speeds

- Largest spindle bores (3"–12") in the turning industry handle large-diameter bar and tube applications and swallow long chucking work

- Multiple longitudinal tool head mounting positions on each turret station for minimal tool overhang and maximum tool rigidity

- Flexible I.D. (boring) tool head design allows easy adaptation to quick-change tooling

- Gang and multiple-tip tooling can be easily mounted on any tool station

- Optional free-standing coolant tank for superior coolant management

- Readily adaptable to super high-pressure (2,000 psi and higher) coolant systems

Heavy-duty, domestically built Bardons & Oliver 2-axis chuckers will handle your most demanding chucking work with ease.