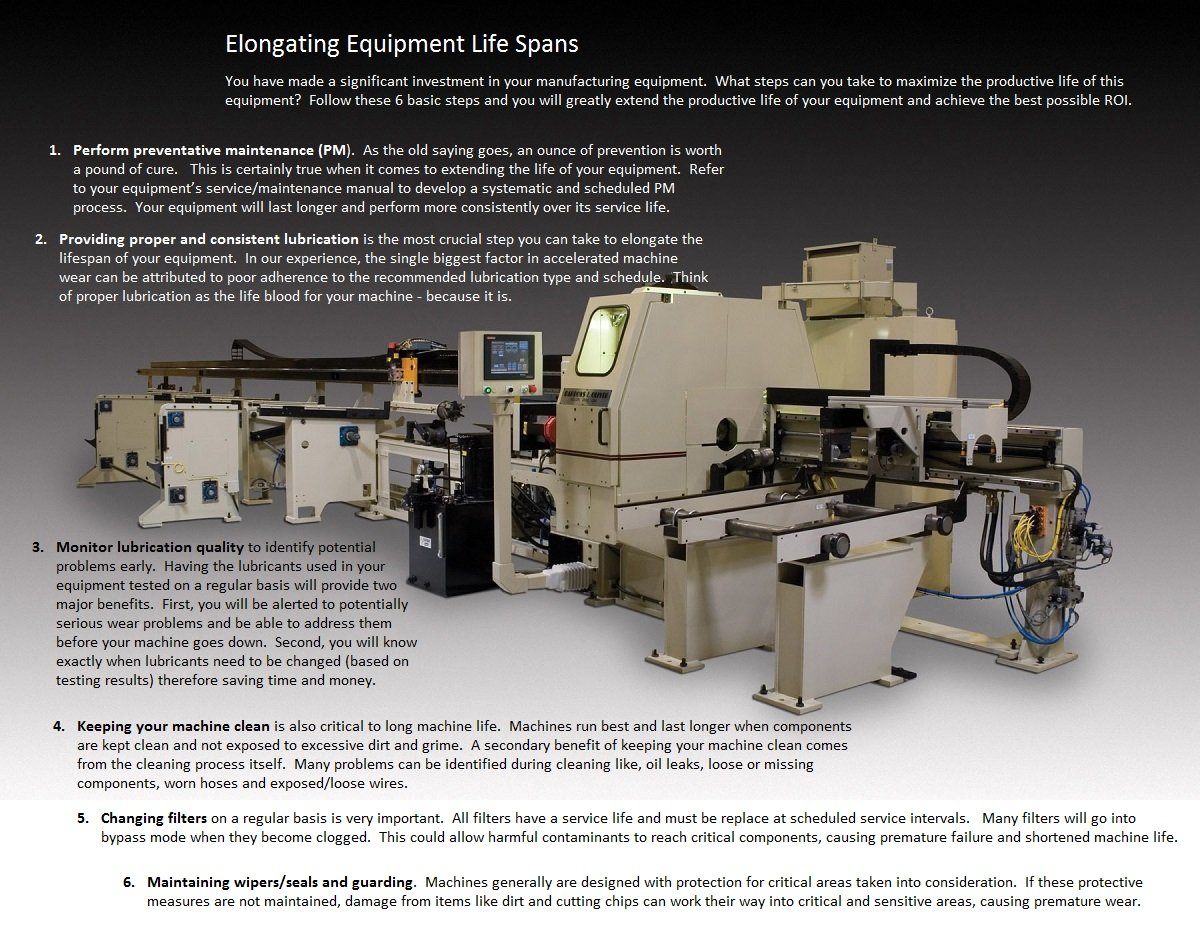

You have made a significant investment in your manufacturing equipment. What steps can you take to maximize the productivity and life of this equipment? Follow these 6 key steps to get the most from your equipment.

Extending Machine Life in 6 key steps.

Dec 20, 2019 2:46:52 PM / by Brett Baldi posted in Insider, Maintenance

Adversity, Leadership, and… Pizza?

Aug 3, 2018 4:09:31 PM / by Travis Miller posted in Insider, job shops

I’ve learned a lot in a short time about being a leader. The list of positives and successes far outweigh the challenges and failures, yet much like everything in life there are ebbs and flows, good times and bad, peaks and valleys. Being a leader offers up rewarding experiences like:

Ways to Categorize Mandatory Spare Parts

Aug 3, 2018 4:07:14 PM / by Mike Toth posted in Insider, Machine Tool, Maintenance

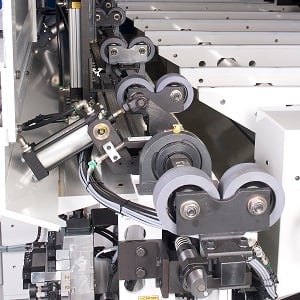

Owning a Bardons & Oliver Machine is a great investment for your company. Maintaining your system will result in many years of productive service for your company. Included with the instruction manual for your machine is a suggested spare parts list. These are necessary parts that will play an important role in keeping your machine running longer and getting it running sooner whenever it has to be taken out of service for preventive maintenance and repair.

Avoiding the Most Common Mistakes in Machining (Focus, Offsets, and You)

Oct 6, 2017 1:35:49 PM / by Travis Miller posted in Insider, Contract Machining

We’ve all done it. You check a bore, an OD, or any feature, make your adjustment, push start and experience that sinking sensation in your gut as you go to check the result. It’s bad. It’s out of tolerance. If you’re lucky, you just have to adjust and cut it again. If you’re really unlucky, you crash the machine and the rest of your day is spent trying to recover.