ISO 9000 provides a solid structure for managing processes within an organization. The importance lies in the benefits of implementation:

The Importance and Advantages of ISO 9000 Certification

Aug 31, 2018 4:06:10 PM / by Cedric Ridgeway posted in Contract Machining, CMM, job shops, gage calibration

Machining with Pride

Aug 20, 2018 2:38:54 PM / by Travis Miller posted in Contract Machining, job shops, Machine Shop

We’ve all been told that if we want to succeed in life and in business, that taking pride in what we do is of critical importance. There is a certain thrill that comes from doing something right not just doing something “good enough”.

Precision Turning and Your Large Diameter Project

Dec 15, 2017 3:39:47 PM / by Travis Miller posted in Contract Machining, job shops, Machine Shop

The average human hair measures between .003” and .006”. Now picture a 50” OD with a +/-.001 tolerance. Impressive, correct? Now consider that a 5 degree temperature difference between the part and the piece of inspection equipment used to measure it would throw off the reading by about .0015.

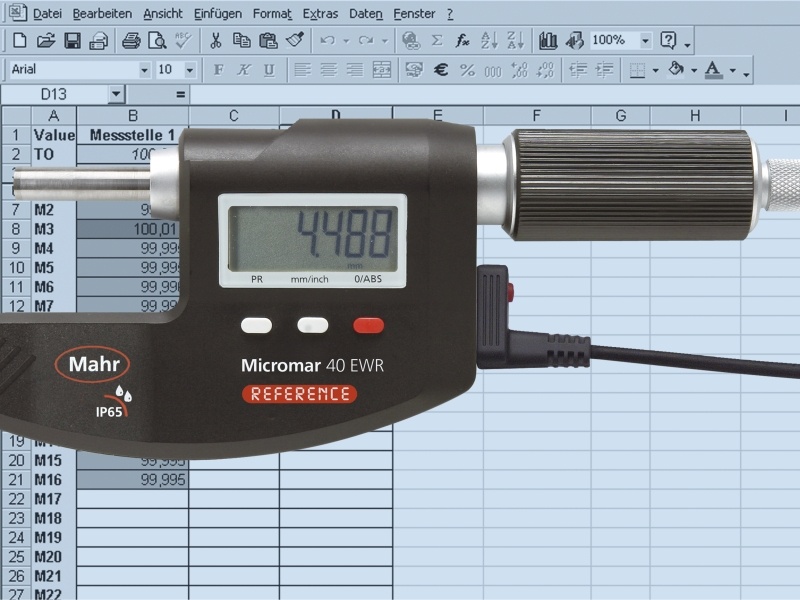

Investing in Quality: Calibrated Gages

Nov 3, 2017 11:04:03 AM / by Travis Miller posted in Contract Machining, gage calibration, iso 9000

Investing in Quality: Calibrated Gages

A master woodworker does not use a beat up yardstick while crafting a beautiful table. A world class clothier doesn’t eye ball your body before crafting an exquisite suit. A 4-star chef will use precise tools to measure ingredients to repeat a spectacular recipe. Why would you trust your precision metal work to a shop who didn’t invest in properly calibrated gages and a staff trained to use them correctly?

Avoiding the Most Common Mistakes in Machining (Focus, Offsets, and You)

Oct 6, 2017 1:35:49 PM / by Travis Miller posted in Insider, Contract Machining

We’ve all done it. You check a bore, an OD, or any feature, make your adjustment, push start and experience that sinking sensation in your gut as you go to check the result. It’s bad. It’s out of tolerance. If you’re lucky, you just have to adjust and cut it again. If you’re really unlucky, you crash the machine and the rest of your day is spent trying to recover.

Top quality questions to ask your contract machining partner

Aug 18, 2017 4:32:31 PM / by Brett Baldi posted in Contract Machining, CMM, job shops

When you’re searching for a contract machining partner to supply the critical parts you need, how can you best determine the supplier(s) that will be able to meet your quality requirements? What questions should you be asking to separate the best from the rest?

Part in the Spotlight: Oil and Gas Industry

Jul 18, 2016 8:00:00 AM / by Bardons & Oliver posted in Contract Machining

Bardons & Oliver Contract Machining can handle raw material up to a 7′ cube.

Dimensions: 53” long x 37” OD x 21.5” ID Weight: 3,100 lbs.

Part in the Spotlight: 316 Machine Spindle

Feb 10, 2016 8:00:00 AM / by Bardons & Oliver posted in Contract Machining

Today’s “Part in the Spotlight” is a Bardons & Oliver 316 Machine Spindle, created as a replacement part for a major manufacturer in the metals industry.

Meet Cedric Ridgeway, Quality Manager

Jun 25, 2015 8:00:00 AM / by Bardons & Oliver posted in Contract Machining

Cedric Ridgeway, Bardons & Oliver’s Quality Control Manager, ensures that our product meets or exceeds our customers’ standards.

Q: How long have you been in quality control? Where did you get your start?

A: I officially started my career in quality in 1999, when I was promoted to Quality Manager. I had years of experience in machining, inspection, and CNC programming, but no training in quality disciplines. My first project as quality manager was to work with the entire staff to develop a formal quality management system and achieve ISO 9000 certification of that system. With the help of others within the company and an outside consultant, we were certified. During that time I received quite an education in systems, processes, and documentation. An ASQ course in quality engineering was very helpful. Much of what I needed to know came from my shop training and experience.

Part in the Spotlight: Packaging

Jun 4, 2015 8:00:00 AM / by Bardons & Oliver posted in Contract Machining

Packaging Equipment

This multipart assembly was machined to tight tolerances with a detailed finish — to a ‘Swiss watch movement’ precision

Stainless Steel 16″ x 20″, 200 pounds