Owning a Bardons & Oliver Machine is a great investment for your company. Maintaining your system will result in many years of productive service for your company. Included with the instruction manual for your machine is a suggested spare parts list. These are necessary parts that will play an important role in keeping your machine running longer and getting it running sooner whenever it has to be taken out of service for preventive maintenance and repair.

Ways to Categorize Mandatory Spare Parts

Aug 3, 2018 4:07:14 PM / by Mike Toth posted in Insider, Machine Tool, Maintenance

History, tradition & expertise: what is important to you when choosing a Machine Tool Partner?

Feb 16, 2018 4:26:49 PM / by Jon Beattie posted in Machine Tool

Deciding to purchase a new machine can be a complex task. There are many decision makers and influencers involved to help evaluate current production needs and future business growth. The most successful companies know the importance of having the best possible machine tool partner in order to make their project flourish.

B&O’s Latest Control Retrofit: Giving Trusted and Reliable Equipment New Life

Dec 8, 2017 3:58:19 PM / by Jon Beattie posted in Machine Tool, Company News

B&O’s Latest Control Retrofit: Giving Trusted and Reliable Equipment New Life

High Performance Cutoff Equipment for Your Steel Service Center Needs

Aug 30, 2017 11:23:19 AM / by Jon Beattie posted in Machine Tool, Company News

In today’s competitive market, offering your customers value-added solutions allows them to reduce costs and increase capacity. Providing more complete parts in less steps creates a streamlined manufacturing process.

Flex Line Machine Tool with Robotic Automation

May 10, 2016 8:00:00 AM / by Bardons & Oliver posted in Machine Tool

Bardons & Oliver’s RH Flex Line provides flexibility when pair with FANUC Robotics. As a FANUC Robotics integrator, we’re capable of providing a tailored system for specific requirements. Our equipment reduces operating costs and is capable of running unattended for hours. Whether you’re processing straight cut-offs or cut-offs with chamfers and bores, the Flex Line is an excellent machine to give your company the competitive advantage. Bardons & Oliver’s Flex Line offers the largest thru bore options in the industry. Our through bores range from 4.50” up to 13.00” and can process tubing as small as .625” and up to 13.00” with varying wall thicknesses.

We’re Building Another Machine Tool!

Apr 26, 2016 8:00:00 AM / by Bardons & Oliver posted in Machine Tool

Bardons & Oliver is currently building a machine tool specifically for the hydraulic and pneumatic cylinder market. One of our many customers producing hydraulic cylinders purchased a B&O 2SC-850 fully automated CNC Machining System. The machines highlights include a FANUC CNC Control, a Renishaw probe system, live tooling with thru-tool coolant, and large capacity thru bore (8.50” diameter). The spindle system boasts 1,600 maximum rpm and 50 max horsepower spindle motor.

Our TEP-300 – Boiler Tubes R Us

Apr 20, 2016 8:00:00 AM / by Bardons & Oliver posted in Machine Tool

The TEP machine was originally designed to meet the needs of boilermakers, by providing functionality for boiler tube processing. We began producing turning systems for this use in the 1960s. Bardons & Oliver has done installations of boiler tube systems in factories around the world. Of late, this has been especially significant in India’s power generation sector, which is growing thanks to an expanded demand for electricity — expected to cross 950,000 mW by 2030.

Bardons & Oliver – Newest Rotating Head Machine – RH450HP

Apr 14, 2016 8:00:00 AM / by Bardons & Oliver posted in Machine Tool

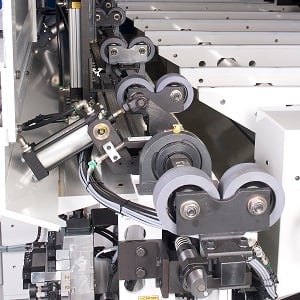

Bardons & Oliver is excited to announce our newest addition to the Rotating Head Series Cut-off Systems. B&O’s RH450HP Rotating Head Cut-off Lathe is a completely new machine built for small, lightweight, extremely FAST tube processing. Designed specifically for thin wall tubing ranging from .028” (.71mm) to .312” (7.94mm) wall thickness, tubing diameters from .750” (19.05mm) up to 4.500” (114.3mm) diameter. Our integrated material handling system includes a fully automatic raw material bundler/unscrambler loading table. Cycle times ranging from 6 to 8 seconds part to part. With full wrap work holding, the machine will not deform tubing, providing clean cutoff parts with nearly zero kerf by utilizing 3mm cut-off blades to minimize material loss.

More Information on #316 Machines from Tube & Pipe Technology

Oct 9, 2015 8:00:00 AM / by Bardons & Oliver posted in Machine Tool

Bardons & Oliver had an article published in the September 2015 edition of Tube & Pipe Technology about the #316 automatic cutoff lathe we built for a customer.