440.498.5800

5800 Harper Road • Solon, OH 44139

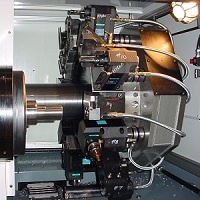

Do you have a Bardons & Oliver CNC Turning Machine that needs a tune up? We have the expertise to keep your valuable work horse up to date with entire machine rebuilds right here in our shop, stripping it down completely and rebuilding it from the machine base up. If a CNC retrofit or a technical upgrade is needed, that is also our specialty.

Can't take your machine out of service to get it rebuilt? Not a problem. We can build you a like-new machine and when it’s done take your old one in on trade, or rebuild or replace critical parts on your floor. Please call for pricing.

Midwest Customers

Call 440-498-5800 x228

All other areas including international customers

Call 440-498-5800 x228

1SC-350, 2SC-500, 2SC-650, 2SC-850 & more

BASE MACHINE COMPONENTS:

REMANUFACTURE X-AXIS DRIVE SYSTEM

REMANUFACTURE Z-AXIS DRIVE SYSTEM

UPGRADE TURRET INDEX SYSTEM

2SC-500 SPINDLE REBUILD (AT B&O)

2SC-650 SPINDLE REBUILD (AT B&O)

MACHINE ACCESSORIES:

2SC HEAVY-DUTY PERFORATED BELT CHIP CONVEYOR

CHIP SHREDDER SYSTEM FOR EASY DISPOSAL OF STRINGY CHIPS

OIL SKIMERATOR SYSTEM (KELLER TKO-6 OR TKO-14)

MIST COLLECTION SYSTEM (TORIT WSO-15)

LIVE TOOLING:

10-HP, 4-STATION, TURRET MOUNTED LIVE TOOLING SYSTEM

HYDRAULIC SPINDLE CLAMP SYSTEM

2SC RADIAL LIVE TOOL HEAD (EACH)

2SC RADIAL QUICK-CHANGE LIVE TOOL HEAD (EACH)

QUICK-CHANGE ER32 COLLET CHUCK (EACH)

2SC AXIAL LIVE TOOL HEAD (EACH)

STOCK-STOP NOSE & SLIDE REBUILD:

STOCK-STOP NOSE, SLIDE, & CARRIAGE REBUILD

BAR & TUBE LOADING SYSTEM:

B&O AUTOMATIC MAGAZINE BAR & TUBE LOADING SYSTEM REBUILD

CALL FOR PRICING

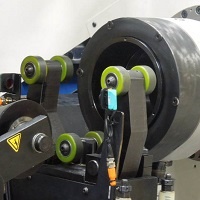

STEADYREST ROLLER ASSEMBLY

2.00" GREEN NYLOIL

STEADYREST ROLLER ASSEMBLY

2.25" GREEN NYLOIL

B&O STEADYREST MISTER SYSTEM

B&O SYSTEM ALIGNMENT

UNLOADER REBUILD:

B&O AUTOMATIC FINISHED PART STEADYREST-UNLOADER SYSTEM

UNLOADER ROLLER ASSEMBLY

UNLOADER ROLLER ASSEMBLY

PIN STAMPING SYSTEM:

AUTOMATED PIN STAMP STATION

FANUC CNC CONTROL:

EWON REMOTE VPN ETHERNET COMMUNICATION SYSTEM

TURRET TOOLING:

2SC RH OD TURNING TOOL HEAD

2SC ID BORING TOOL HEAD

2SC QUICK-CHANGE OD TURNING TOOL HEAD

2SC QUICK-CHANGE OD TURNING TOOL HEAD

HEAVY-DUTY CUT-OFF BLADE HOLDER (.196" WIDE CUT-OFF INSERT) (136480)

SANDVIK 151.2-56-50-8 CUT-OFF BLADE

SANDVIK 151.2-500-5E (1125) INSERTS

SERVICE & TRAINING:

FIELD SERVICE (PER-DAY)

$1,480.00

TERMS & CONDITIONS:

QUOTED PRICE DOES NOT INCLUDE TRAVEL TIME

QUOTED PRICE DOES NOT INCLUDE TRAVEL & LIVING EXPENSES

ALL TRAVEL & LIVING EXPENSES BILLED AT COST

THE QUOTED LABOR PRICING IS AN ESTIMATE

FINAL PRICE WILL BE BASED ON ACTUAL HOURS WORKED

WEEKDAY RATE = $185.00 PER-HOUR

OVERTIME RATE = $277.50 PER-HOUR

SATURDAY RATE = $277.50 PER-HOUR

SUNDAY RATE = $370.00 PER-HOUR

TRAVEL RATE = $100.00 PER-HOUR

WEEKEND & HOLIDAY TRAVEL RATE = $200.00 PER-HOUR

PARTS DEPARTMENT - MIKE MCCLUNG 440-498-5800 x332

FIELD SERVICE - BOB LANGSTON/RON ADAMS 440-498-5800 x333

2.25" GREEN NYLOILDIS-ASSEMBLE AND CLEANINSPECT FOR DAMAGED OR WORN PARTSREPLACE PERISHABLE HARDWARE

This distinction exemplifies the superb quality, design, and delivery results that have made us leaders in the Machine Tool and Contract Machining business.