For Sale:

For Sale: #36 Automatic cutoff lathe

Feb 7, 2023 2:21:45 PM / by Naomi Walters posted in Machine Tool

the art of precision scraping

Aug 18, 2020 10:47:46 AM / by Naomi Walters posted in Contract Machining, Machine Shop

Modern technology has certainly made an impact in the machining manufacturing world with automated processes. But one process still done manually at Bardons & Oliver is precision scraping To be able to hone a piece of metal to perfect flatness takes experience, skill, and talent. It is, in essence, an art. Bardons & Oliver’s very own Jeff Nosky has that skill.

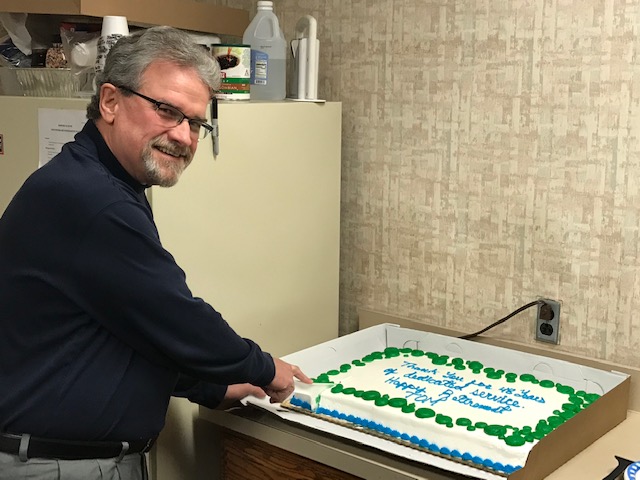

Employee Spotlight -Paul Schmidlin

Jul 30, 2020 9:08:46 AM / by Naomi Walters posted in Company News

Paul has worked in various departments in his 13 years of service at Bardons & Oliver. Specifically, service work, machinist and an applications engineer for the machine tool division. Currently Paul is a CNC programmer using Mastercam to program production machines.

There are many factors which can lead to change, growth, and learning opportunities: most of us can safely say we did not see a global pandemic being a huge factor coming into the past 9 months. Yet, here we are, trying to keep ourselves, our loved ones, and each other safe while still attempting to fulfill our business obligations and deliver on due dates and promises made.

A Message from Bardons & Oliver - COVID-19

Apr 1, 2020 11:20:10 AM / by Bardons & Oliver posted in COVID-19 Message

We hope this communication finds you and your loved ones safe and healthy. These are unprecedented times for everyone and we would like to share with you some of the things we are doing to keep our employees as safe as possible:

Please welcome Gene Mack, Purchasing Manager to the Bardons & Oliver team! Gene started in July 2019 and worked closely with Tom Walker until his retirement. Gene comes to Bardons & Oliver with over 20 years of experience in purchasing.

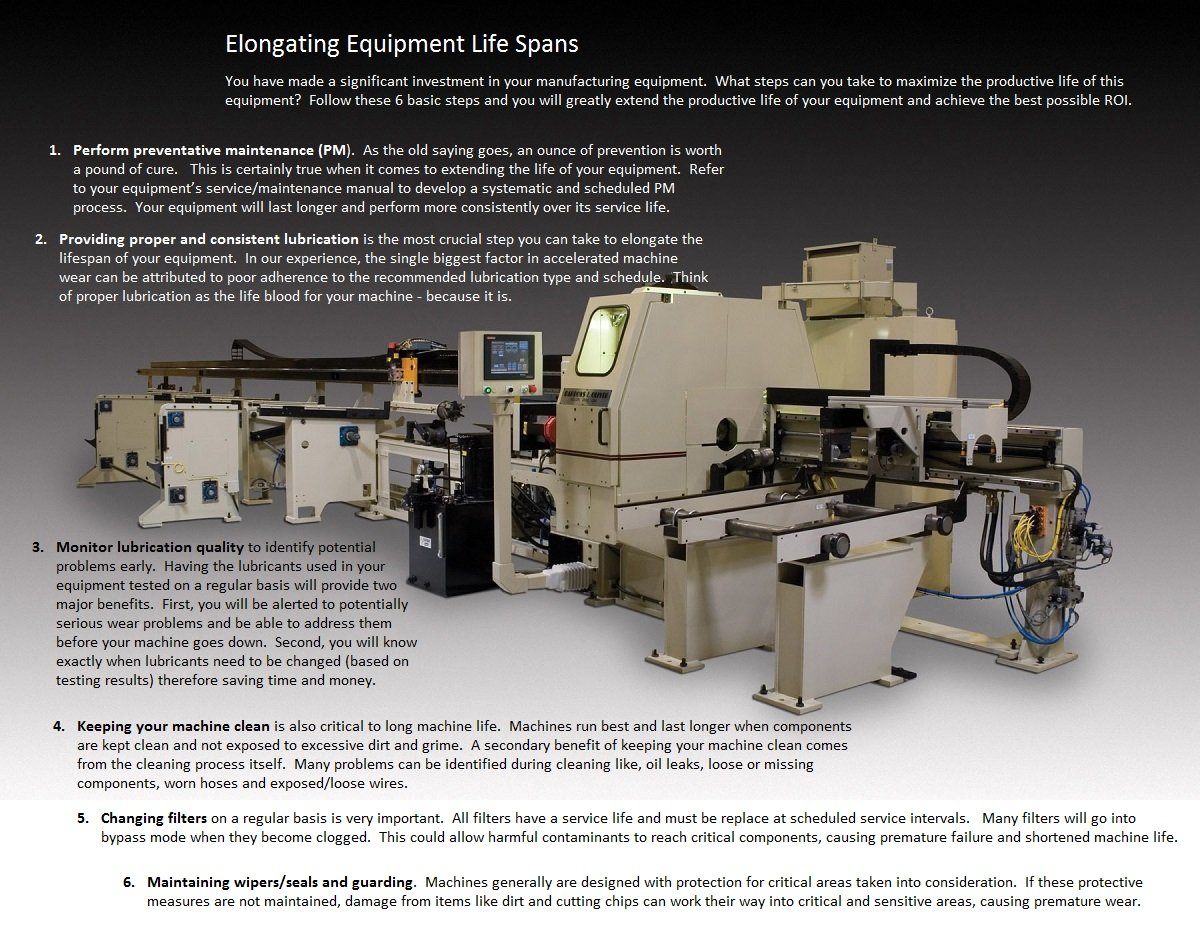

Extending Machine Life in 6 key steps.

Dec 20, 2019 2:46:52 PM / by Brett Baldi posted in Insider, Maintenance

You have made a significant investment in your manufacturing equipment. What steps can you take to maximize the productivity and life of this equipment? Follow these 6 key steps to get the most from your equipment.

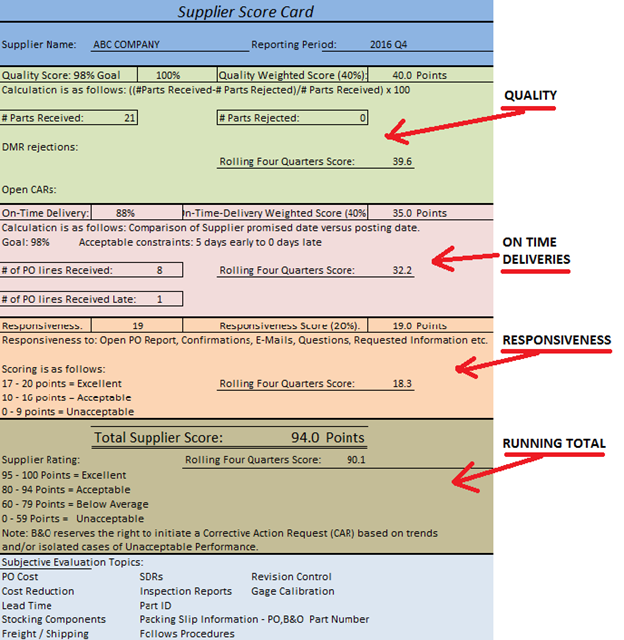

Vendor Scorecard: Rating your Contract Machining Partner for Reliability, Quality, and Timeliness

Dec 7, 2018 3:25:30 PM / by Mike Toth posted in Insider, job shops

Get higher quality products, receive more on time deliveries and obtain highly attentive service from all of your suppliers without paying more for your purchases. Does this sound like the first line from a TV infomercial? Well it isn’t. Developing a Vendor Scorecard Rating system will get you these results, fast.

The Importance and Advantages of ISO 9000 Certification

Aug 31, 2018 4:06:10 PM / by Cedric Ridgeway posted in Contract Machining, CMM, job shops, gage calibration

ISO 9000 provides a solid structure for managing processes within an organization. The importance lies in the benefits of implementation: